Automatic Powder Coating production Line Electrostatic spraying drying curing complete equipment

Overview

Inquiry

Related Products

Automatic Powder Coating production Line Electrostatic spraying drying curing complete equipment

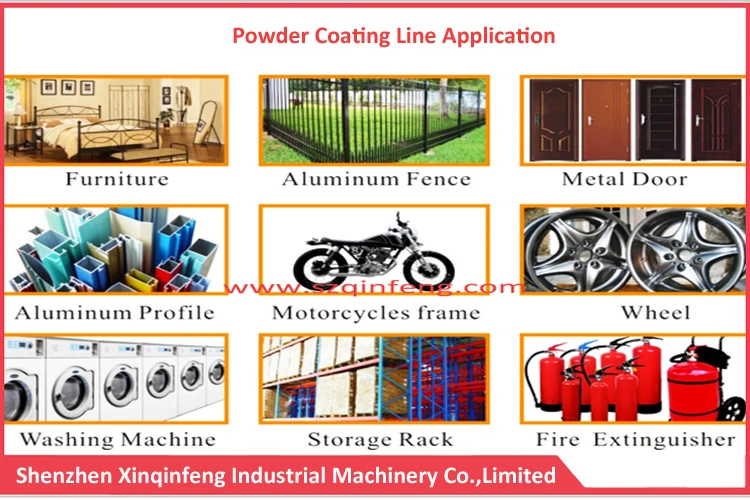

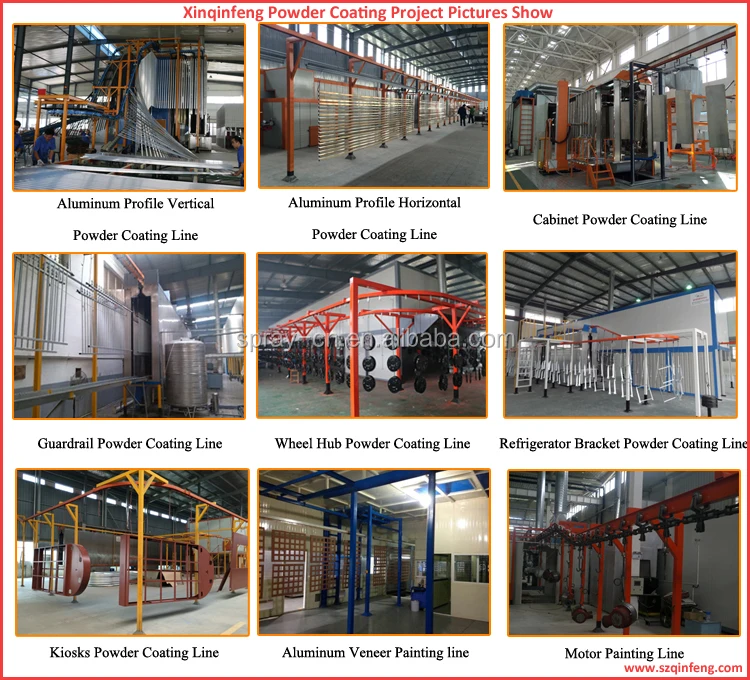

Powder Coating Spray Line Introduction:

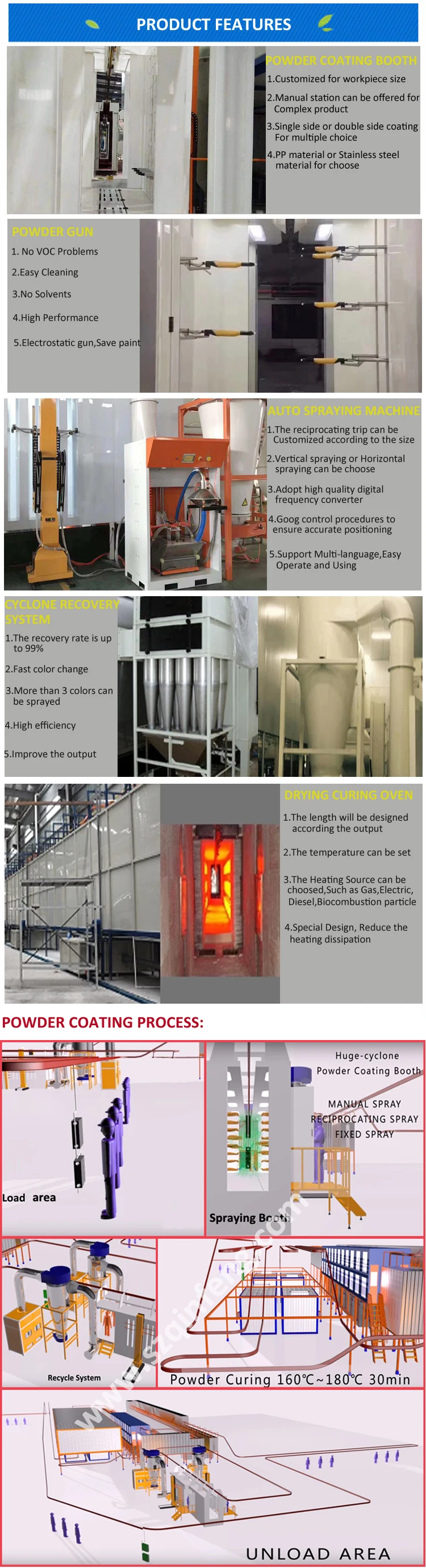

The components of the coating line mainly include: pre-treatment equipment, dusting system, Powder coating equipment, powder recycling equipment, heating drying curing tunnel furnace, heat source system, electronic control system, suspension conveyor chain and so on.

General Metal Material Coating Process:

First, the pre-treatment: purpose: to remove the surface of the workpiece generated by a layer of anti-corrosion and can be applied with the coating adhesion of the "phosphating layer" main process steps: degreasing, derusting, phosphating, passivation. After the pre-treatment of the workpiece, not only the surface has no oil, rust and dust, but also a gray and white shiny surface produces a uniform and rough rust-free gray phosphating film, which can both rust and increase the adhesion of the sprayed layer. . Related equipment: pre-processing bad. Related materials (chemicals) sulfuric acid, hydrochloric acid, soda ash, acid degreaser, phosphating solution, passivation solution.

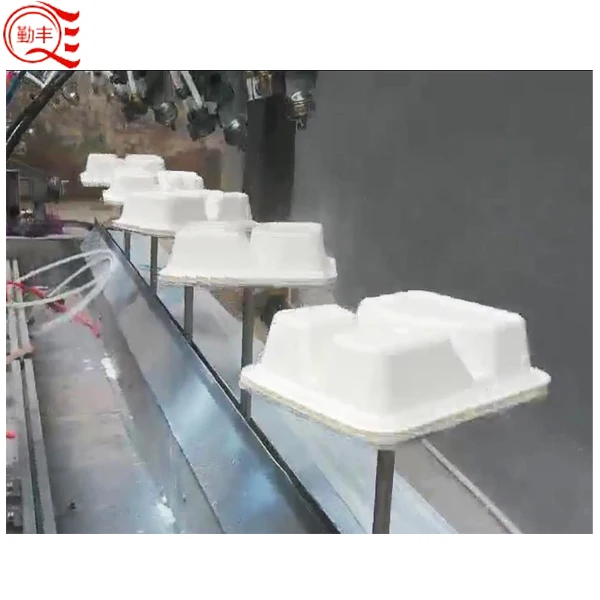

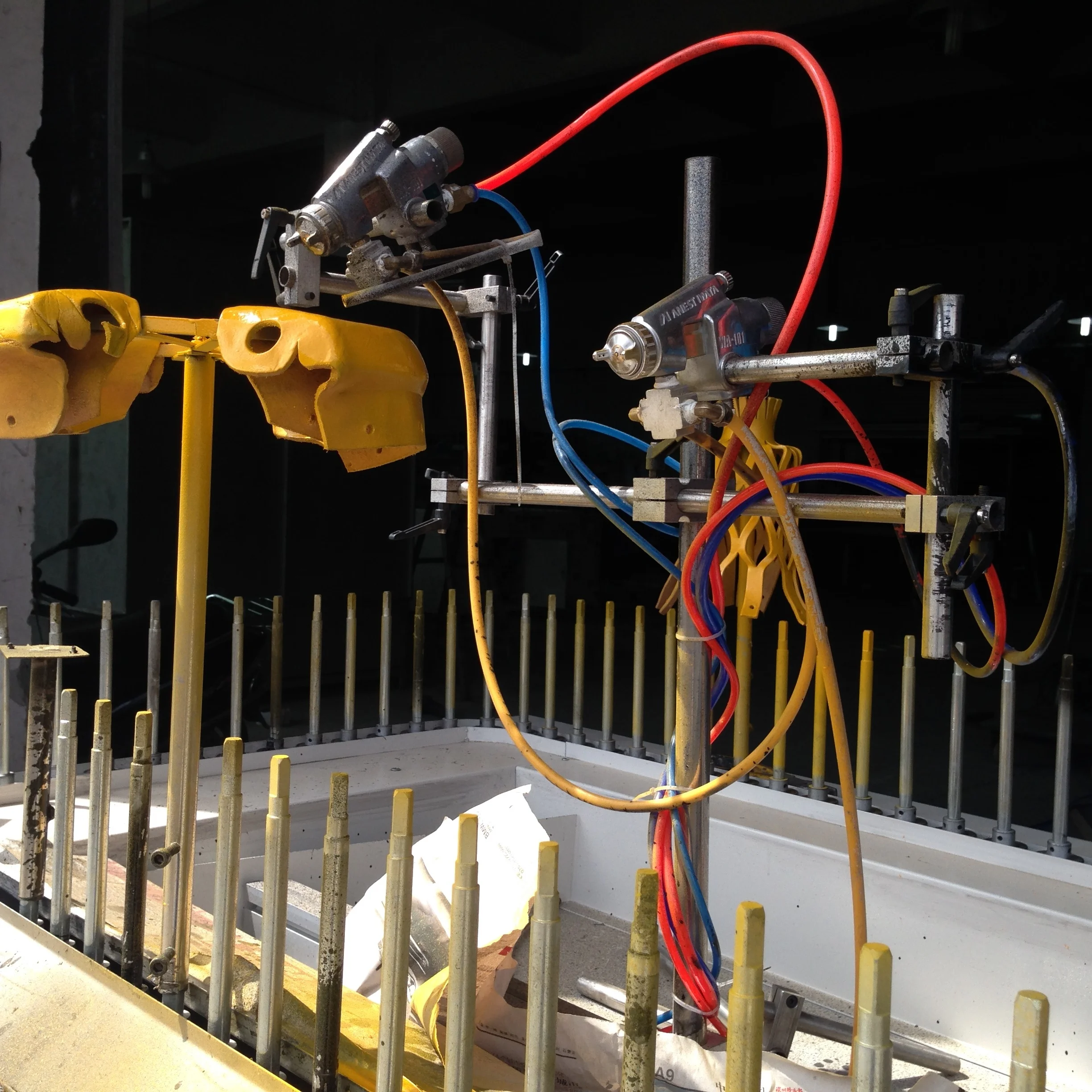

Second, electrostatic spraying: purpose: the powder coating is evenly sprayed onto the surface of the workpiece, special workpieces (including the location where the electrostatic screen is prone to occur) should be finished with a high-performance electrostatic spray machine. Process steps: Using the adsorption principle of the electrostatic spray machine, a layer of powder coating is sprayed evenly on the surface of the workpiece; the dropped powder passes through the recovery system and can be reused after being sieved.

Three. Air compressor and compressed air purifier (oil water filter) related materials: powder coating (spraying raw materials, commonly known as "plastic powder", with high light, bright light, semi-matt, matt, sand, hammer, crack, etc. Different effects and different colors)

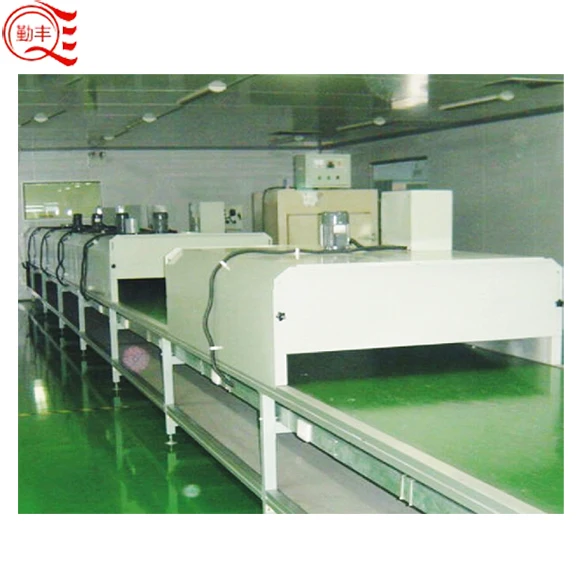

Four. Drying and curing: Purpose: The powder coating on the surface of the workpiece is heated to the specified temperature and kept for a corresponding time to melt, level and solidify, so as to achieve the desired surface effect of the workpiece. Process: Push the sprayed workpiece into the curing oven, heat it to a fixed temperature (typically 185 degrees), and keep it for the corresponding time (15 minutes). Heating and control systems (including electric heating, fuel, gas, coal, biomass heating, new heating materials, etc.) related equipment: biomass burners (various heating equipment), drying tunnels.

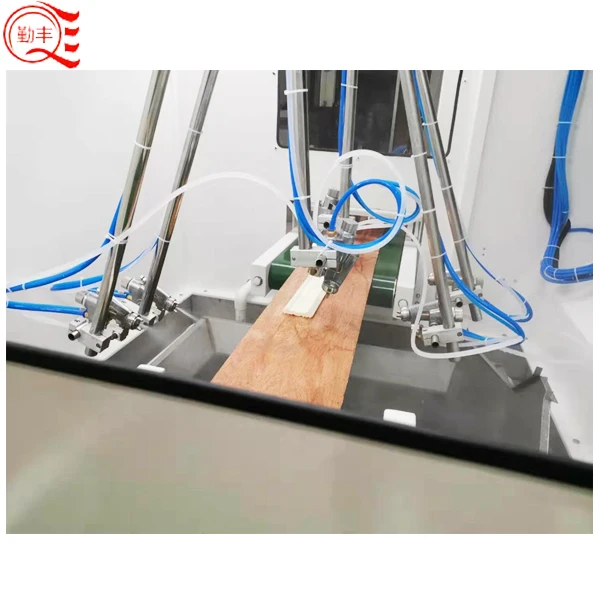

Five, Decorative treatment: purpose: to achieve a certain special appearance of the workpiece after electrostatic spraying, such as: a variety of wood grain, pattern, lightening and so on. Process steps: cover light, transfer and other processing techniques.

The main process flow of the coating production line:

Loading Product → pre-treatment → dehydration drying → cooling → electrostatic powder (paint) spraying → powder (paint drying) curing → cooling → inspection → Unloading Product→Package

Product Show

Other Hot Product

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ