Overview

Inquiry

Related Products

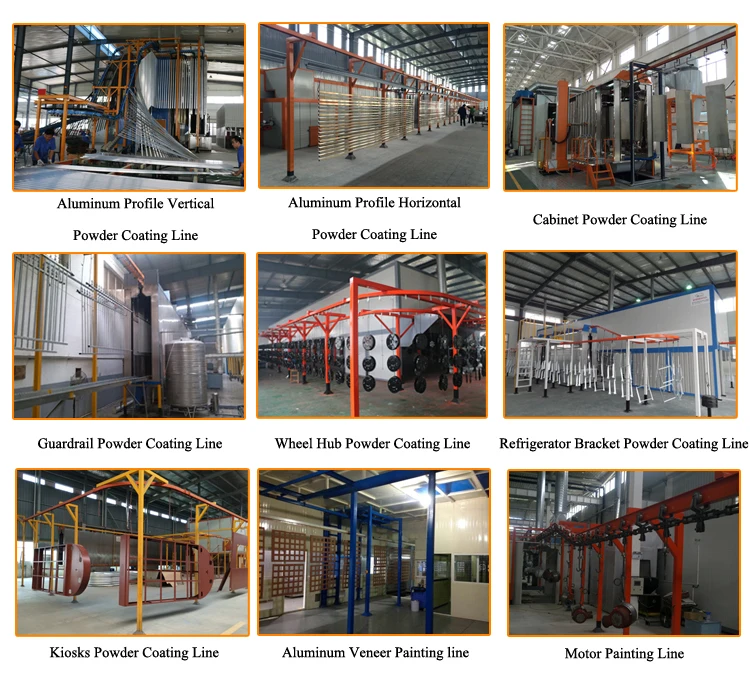

The Xinqinfeng completely Automated Powder Finish Paint Line System would be the

choice

that is actually utmost the smooth and powder layer therapy that is efficient. This will be actually advanced level it is feasible to layer an alternative solution of products with powder paint without losing any complete mins or powder using this system that is specific. The work that is user-friendly an element that is organizations which is often people that are excellent to boost their production therapy.

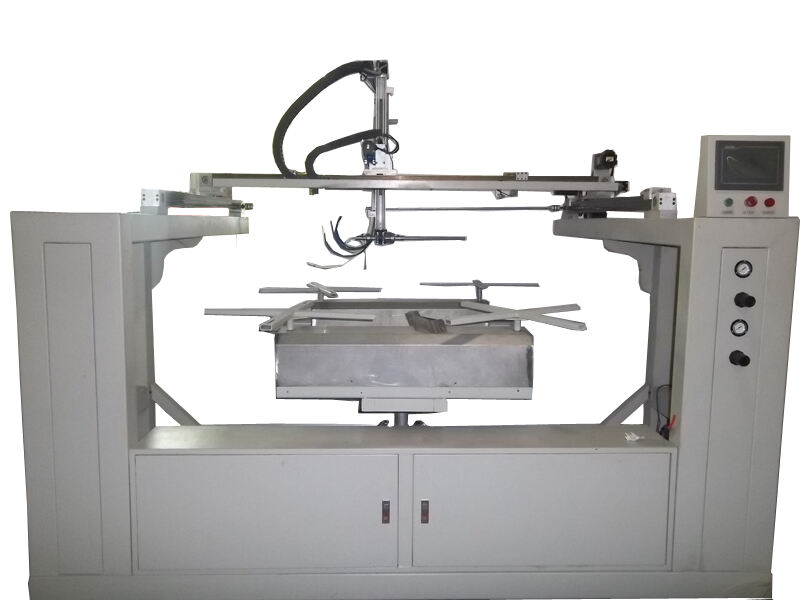

The Xinqinfeng completely automated Powder Finish Paint Line System is produced with state-of-the-art aspects and technology that is advanced supplying a protected and satisfaction this is really trusted. The product has different things containing something system this happens to be system that is positively managing is powder that is workstation that is pre-treatment and range that's handling. Each among these products work completely with every other which could make certain efficient, consistent, and powder this is really results that are top-notch.

A site could be acquired by you this is really individualized pleases your needs being whole are unique combined with the Xinqinfeng Fully Automated Powder Finish Paint Line System. You shall select from different choices, just like the conveyor measurement, dimension, and range hooks. It is feasible to choose different tones of powder paint for you straight that will effortlessly be sure.

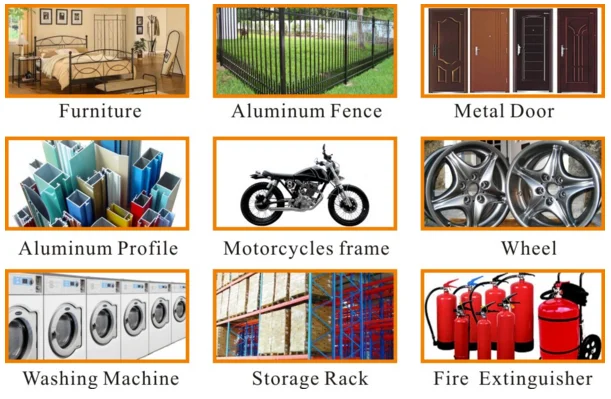

The Xinqinfeng completely automated Powder Finish Paint Line System advantages organizations in the automobile, gear, agriculture, and gear this is really big. The unit have been produced a number of types, measurements, and things, containing aluminum that is lightweight metal, and substances. The gear this might be pre-treatment that the real items are totally washed, degreased, and handled before powder layer, ultimately triggering a protected and layer that is uniform.

The Xinqinfeng completely Automated Powder Finish Paint Line System is actually a work maybe that's keep that's simple with merely downtime that is minimal running that's lowered. Using this method that is practical you'll want a powder this may be therapy that is certainly manufacturing that is not hard your manufacturing is running effortlessly and effortlessly.

Evaporation coating equipment: vertical, horizontal. Machinable products include: mobile phone, DVD, MP3, PDA shells, buttons; cosmetic shells; craft gifts, toys, Christmas gifts; Machinable materials include: ABS, PS, PP, PC, PVC, nylon, metal, Poly , glass, ceramics, TPU, etc. The electroplating effects are: ordinary electroplating bright surface, matte surface (semi-dumb, full-dumb), process electroplating wrinkles, wire drawing, raindrops, colorful, etc.; electroplating colors are: gold, silver, red, blue, green, purple, etc.

Magnetron sputtering + evaporation coating equipment: vertical, horizontal. It is a multifunctional and efficient coating equipment. Rotary magnetron rake, middle rake twin sputtering rake, unbalanced magnetron sputtering rake, DC pulse superimposed bias power supply, etc. can be configured according to user requirements. , glass, ceramics, etc.) workpieces coated with aluminum, copper, chromium, titanium, silver, stainless steel and other metal films or non-metallic and metal-infiltrated DLC films, the coating layer is uniform, dense, and has strong adhesion and other characteristics, which can be widely used in Home appliances, clocks, arts and crafts, toys, car lamp reflectors, mobile phone button shells and instrumentation and other surface decorative coatings and functional coatings for tools and molds.

Multi-arc ion coating equipment: We have matured in the design and processing of this coating equipment, and have been stable in the coating and coating of tools for a variety of ultra-hard ceramic films, including titanium nitride (Tin), titanium carbide (Tic), titanium nitride (Titanium carbide) ( TiCn), zirconium nitride (Zrn), chromium nitride (Crn), titanium aluminum nitride (TiAln), etc. After proper film processing, the life of the workpiece can be increased by 3 to 10 times. It can reduce costs, increase production efficiency and improve product quality. Widely used: craft ceramics, cutting tool industry: such as carbide, drill, milling cutter and other cutting tools. Precision mold industry: standard punch molds, forming molds, etc. Automobile industry: easy-wear parts such as pistons and piston rings.

| Spray the base UV paint---UV Curing----PVD Vacuum coating machine----Spray the top UV paint---UV curing. |

Overview: Evaporative coating device uses resistance heating method in a vacuum chamber to melt and vaporize the metal wire (aluminum wire) that is close to the resistance wire, and the vaporized metal molecules are deposited on the substrate to obtain smooth and high reflection. The high-efficiency film layer achieves the purpose of decorating and beautifying the surface of the item.

Features: Reasonable structure, uniform film layer, good film quality, high pumping speed, short working cycle, high production efficiency, convenient operation, low energy consumption and stable performance.

Uses: automobiles, audio, various small appliances, computers, watches, toys, mobile phones, reflectors, cosmetics, toys and other industries.

Machinable materials: ABS, PS, PP, PC, PVC, Nylon, Metal, Poly, Glass, Ceramic, TPU, etc.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ