Overview

Inquiry

Related Products

-

Online automatic spraying paint,simplify the middle stage from the human load-download workpiece

-

Fully enclosed spray pattern,reduce environmental pollution and man-made damage

-

Steady quality,spraying evenly

-

Automatic spraying,high efficiency, Save labor cost

-

Spraying degugging is simple within ten mins,The program is easy to operate

-

Factory Price,Competitive price

-

High quality,One year Warranty

- Whole factory plastic parts automatic dust coating equipment

- Whole plant metal products electrostatic coating equipment

- Whole factory furniture electrostatic coating equipment

- Whole plant locomotive, motorcycle coating equipment

- Manipulator, Spraying robot etc Industrial Robot equipment

- Automatic UV curing furnace line

- Fully automatic electrostatic dust removal equipment

- DISK automatic electrostatic coating equipment

- All kinds of Drying,silk-screen equipment

- All kinds of PVC/SUS belt,Nylon conveyor equipment

- Teflon/Ceramic powder /PE immersion high temperature equipment

- All kinds of Water Curtain Booth etc equipment

- High level Air Supply System

- Waste water/waste gas recycling system

- Whole plant electroplating coating equipment

- Whole factory electrophoresis coating equipment

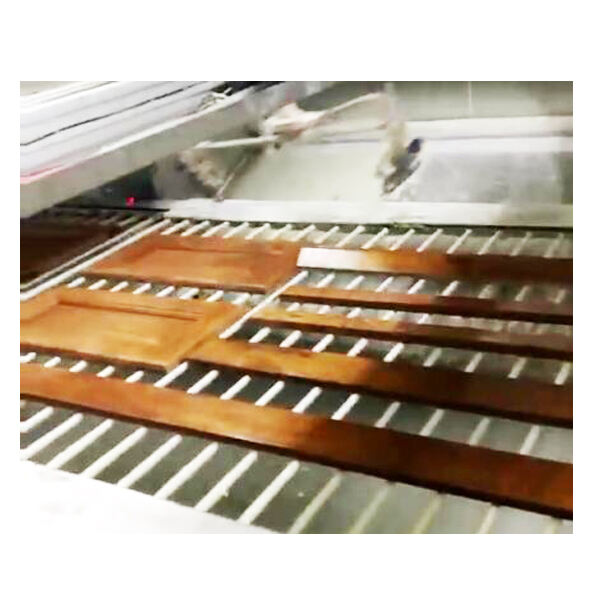

You appear during the woodworking industry; you recognize exactly how important it is to have a smooth and additionally complete within the ongoing solutions you offer and items If you ought to be whenever. But artwork this is really manual be time-consuming, inconsistent, and messy. This is the reason Xinqinfeng has produced an Automatic Spray artwork device for Wood which takes the pain sensation feeling through the task.

The Xinqinfeng Automatic Spray artwork device for Wood is definitely a game-changer for woodworkers who would like to produce quality finishes regarding the services and products. No more worrying about drips, smears, or coats being uneven the unit protects the ordinary thing that is entire. Plus, it might manage a variety this really is actually wide of things and sizes.

Precisely what sets this Automatic Spray artwork device for Wood in addition to the rest is its smart design. It is actually created using high level sensors that may identify the execution that is appropriate proportions of your respective product. This allows the apparatus to place the total amount up that is total is perfect of, no matter what size it is. In addition, it adjusts the spray speed and pattern to make certain that every particular area that's certain evenly covered.

The device is user-friendly acutely. Simply load your merchandise regarding the conveyor gear, adjust the settings, and invite the machine to perform some work. You will probably be astonished at exactly how quickly and effortlessly it is applicable a finish this might be undoubtedly flawless your wood items.

One of many better the different parts of the Xinqinfeng Automatic Spray artwork device for Wood may be the understood undeniable fact that it's eco-friendly. It certainly works within the system this is really closed loop recycles paint, reducing waste and aiding you conserve money. Plus, it really is developed become energy-efficient, which means you'll save well on your electricity bill too.

Security is actually a pressing problem this is actually top which explains why the Xinqinfeng Automatic Spray artwork device for Wood is manufactured with protection features being a crisis end switch and hurdles which can be protective. It is possible to actually sleep comprehending that is easy your group is safe whenever use that is producing of device.

Production Features:

Product Specification:

|

Item |

Remark |

|

The conveyor line |

1.The foot of machine is equipped with the adjustable foot cup . 2. The transmission system use standard carbon steel with heavy load transmission roller. 3. The power system: The motor use taiwan WANSIN brand 1HP gear reducer motor. 4.The transducer useThe taiwan DELTA brand 1HP frequency converter. 5.A set of transmission shaft, transmission parts are equipped with.(the speed range is within 0.1-6m/min) |

|

Water Curtain Spraying Booth

|

1. The bottom bracket is made of 50X50 stainless square box section and equipped with the adjustable M14 foot cup. 2. The tank is made by bending and welding 1.5mm 201# stainless steel sheets.

3. The pump adpots the taiwan vertical pipeline pump. A set of PVC pipe and valve are also equipped. 4. The exhaust fan use a set of Taiwan hongsheng 3HP centrifugal fan.(the air volume is 8000 cubic meters per hour).The ventilation duct is not included and provided by the customer. 5. The light use one 40W explosion-proof light with hood. 6. A set of electric control cabinet is equipped and the electrical accessories use the well-known brand. 7. The filtration system in the top of booth use the non-woven filter screen. |

|

Single Axis Reciprocating engine ( 1 set)

|

1. the effective trip is within 1500mm.(can be customized) 2. The length of guide rail is 1500mm.The sliding rail use 25 series flange type self lubricating linear guideway from Taiwan Hiwin brand with aluminum alloy module slider. 3. The sliding module adopt 65x65mm special aluminium for the reciprocating engine. 4. The PLC use Taiwan FATEK ,The speed and trip can be adjustable. 5. The HMI use the Beijing MCGS 7 inch color touch screen. All adjustable parameters can be visualized and the button operation is simple. 6. The motor use the 400W low-inertia servo motor driving from Taiwan DELTA brand. 7. A set of electric control cabinet is equipped and the electrical accessories use the well-known brand. 8. 5M type synchronous wheel drive,the reciprocating synchronous belt adopts L special steel wire belt. 9. The speed is 1-3m/mins(can be customized). |

|

Automatic spray gun and oil supply ( 1 set) |

1. Automatic spraying guns:Japan ANEST IWATA brand WA-101 series automatic spraying. The Japan ANEST IWATA brand 101 series automatic spraying gun with the calibre is 1.0mm. The qty is 2pcs. 2. A set of Taiwan diaphragm pump is equipped.the caliber is trisection. 3. A set of Oil pipe, air pipe,oil-water separator, pressure regulating valve, electromagnetic valve are equipped. |

|

Electrostatic Precipitation

|

The domestic electrostatic iron wind stick is installed in the feeding area. Firstly dust off the product, Then enter the spraying room. |

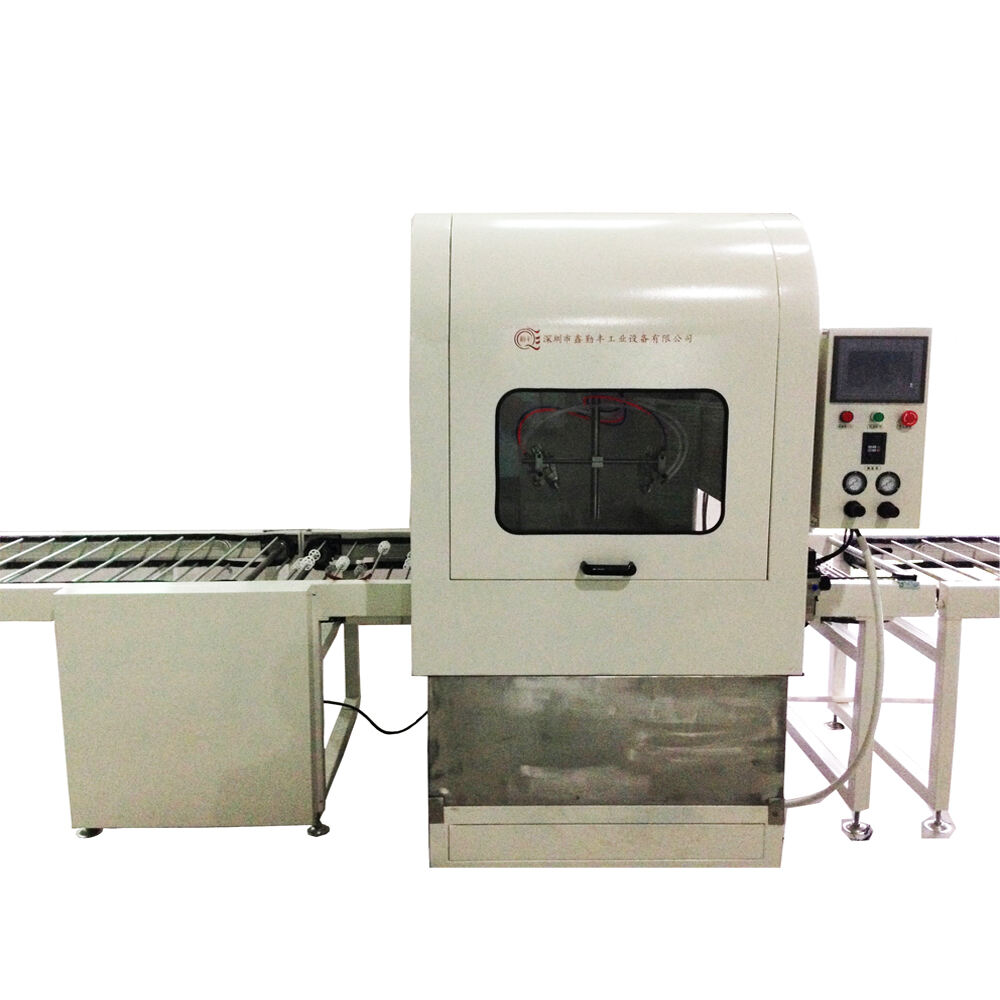

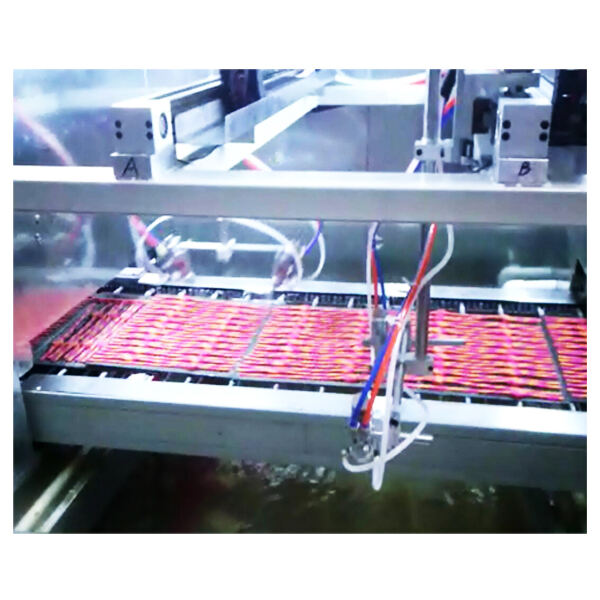

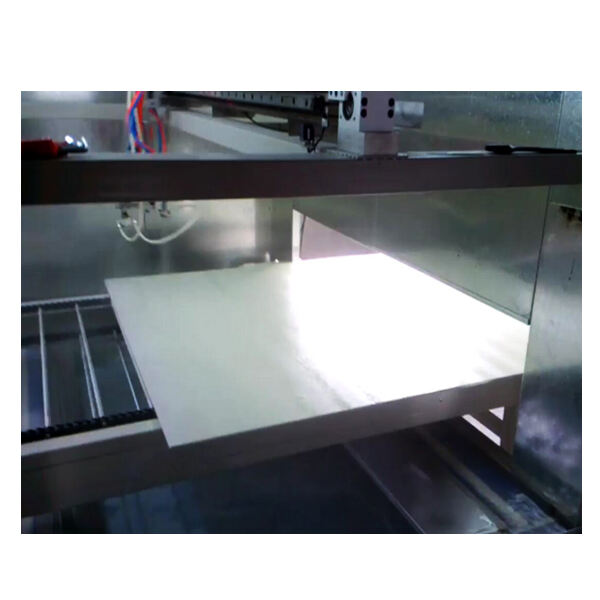

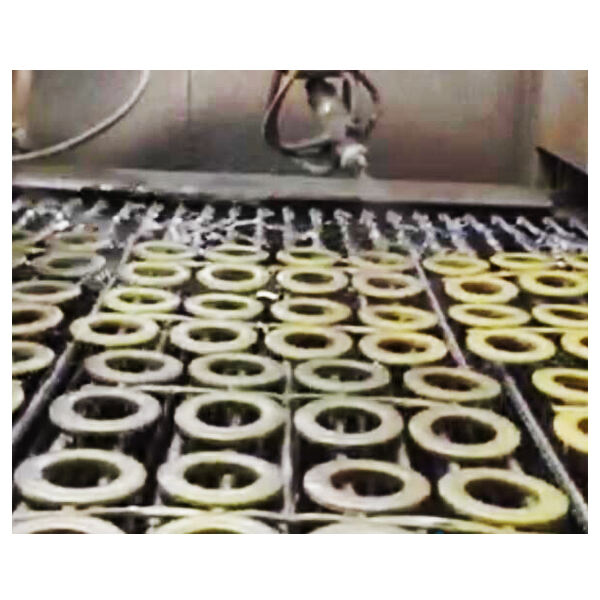

Product Pictures:

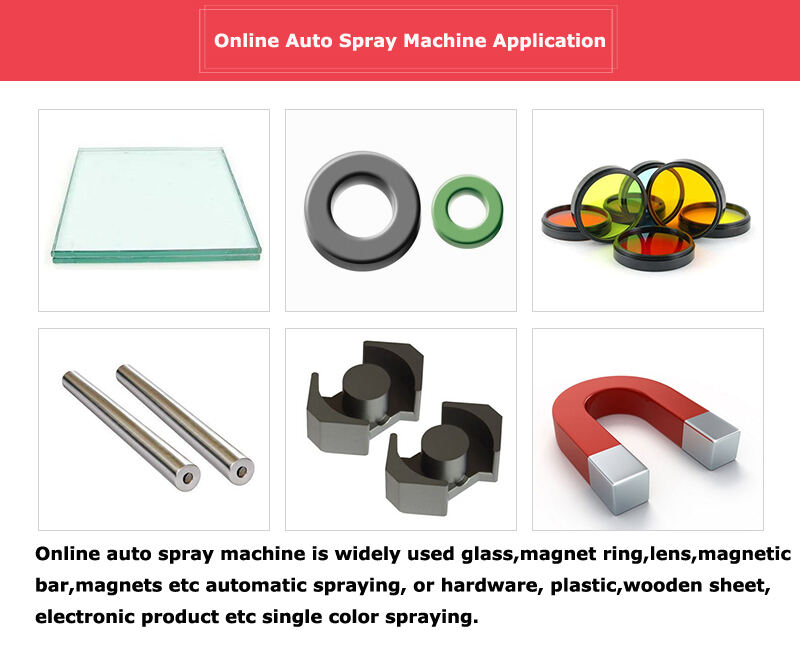

Application:

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries.From a development department,Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment.After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

Our Service

Our products are widely used in surface treatment of automobiles and auto parts, household

appliances, medical equipment, metal products, construction machinery, mechanical and

electrical products, motorcycles and other metal products, wooden furiture, plastic products

and other types of products.

Pre-sales:

1. Offer professional advice and provide the best solution for the customer

2. According to customer's needs or requirements, Our engineer will offer the drawing and solution for you.

3. We will offer the competitive price according to the customer's solution

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

If you can send us some pics about your product with capacity per day and size for first reference. Once get your infos, We will send you our solution with price ASAP.Appreciating for your support!

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ