Overview

Inquiry

Related Products

- Whole factory plastic parts automatic dust coating equipment

- Whole plant metal products electrostatic coating equipment

- Whole factory furniture electrostatic coating equipment

- Whole plant locomotive, motorcycle coating equipment

- Manipulator, Spraying robot etc Industrial Robot equipment

- Automatic UV curing furnace line

- Fully automatic electrostatic dust removal equipment

- DISK automatic electrostatic coating equipment

- All kinds of Drying,silk-screen equipment

- All kinds of PVC/SUS belt,Nylon conveyor equipment

- Teflon/Ceramic powder /PE immersion high temperature equipment

- All kinds of Water Curtain Booth etc equipment

- High level Air Supply System

- Waste water/waste gas recycling system

- Whole plant electroplating coating equipment

- Whole factory electrophoresis coating equipment

Xinqinfeng

Industrial Automatic Painting Robot Arm Machine is certainly a solution is very good artwork big industrial areas with accuracy and effectiveness. This machine combine’s higher level technology is robotic state-of-the-art programming to provide stunning results every time.

This system is revolutionary a high-tech arm robotic with the capacity of painting large commercial areas with a high level of accuracy. The Xinqinfeng Industrial Automatic Painting Robot Arm Machine is able to accomplish tasks which are beyond the power of conventional artwork gear featuring its revolutionary design and cutting-edge technology.

Featuring a straightforward and easy man or woman who is intuitive, it is simple to plan this artwork robot supply device to deliver impressive results. Also, the equipment is built to be very flexible, which makes it simple to adapt to painting this is certainly significantly different and requirements.

Using the Xinqinfeng Industrial Automatic Painting Robot Arm Machine, you should not bother about the laborious and task are very time-consuming of large spaces that are commercial. The merchandise is effective at areas are painting and are large rate of accuracy, assisting you to save your time, money, and effort.

The Xinqinfeng Industrial Automatic Painting Robot Arm Machine will be the perfect solution whether you are looking to repaint a sizable commercial center or handle a high-volume production line. This method delivers constant results which are both precise and efficient, rendering it a musical instrument this is certainly highly sought-after many industrial applications.

Production Features:

1. The painting is precise, the normal run time is long, the paint consumption is less. It runs 24 hours and has higher reliability.

2. The painting speed is quick and even. The user can automatically adjust the painting height, direction, angle position based on parts. The painting control is flexible. Omnidirectional painting can be achieved.

3. It is anti-explosion, and environment friendly. It has higher safety, and the operation control

is easier to learn.

4. Spraying painting robot can paint 2 or 5 kinds of product simultaneously.

5. Spraying painting robot has long service life and easier maintenance.

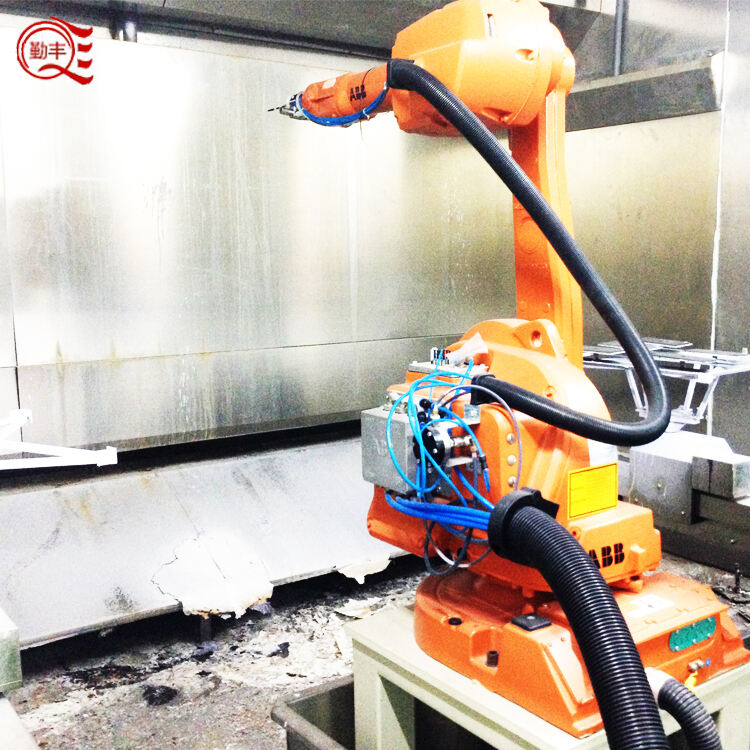

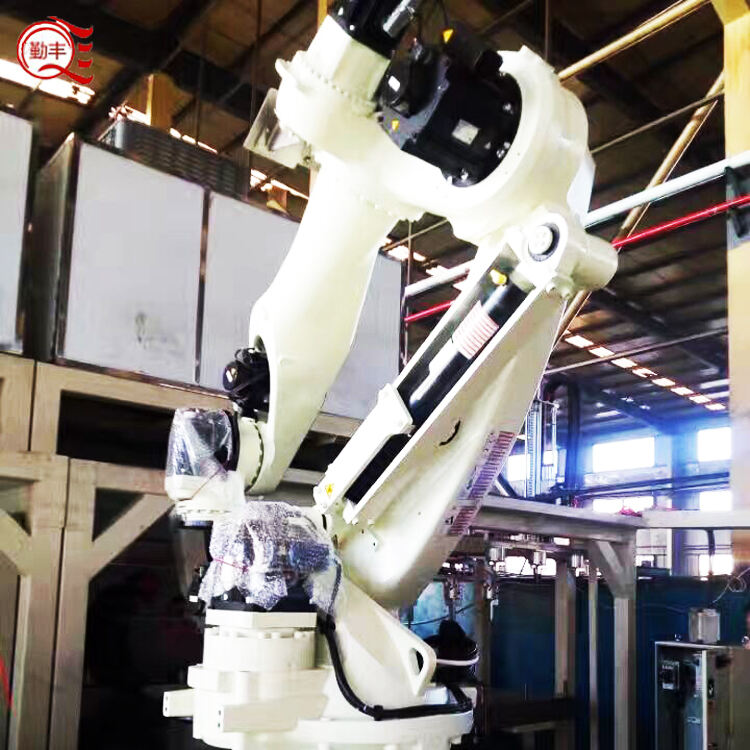

Product Pictures:

|

No. |

Items |

Specification |

|

|

1 |

Brand |

Kawasaki spraying robot |

|

|

2 |

Body Parameter |

maximum load bearing |

5KG |

|

|

|

Degree of Freedom |

6 Axis (JT1,JT2,JT3,JT4,JT5,JT6) |

|

|

|

Maximum Radium of Activity |

1000MM |

|

|

|

Installation Type |

Install the seat to be mounted upside down |

|

|

|

Driver Type |

Kawasaki AC servo drive |

|

|

|

IP Degree |

Intrinsically safe and pressurized Level 1, Zone 1, Group IIB and T4 certification |

|

|

|

Repeated Positioning Accuracy |

±0.2MM |

The Main Features of Spraying Robot:

1. Increasing the production efficiency, widely using in various fields

2. High spraying efficiency, best finishing quality;

3. Automatizing the paint process;

4. Less maintenance equipment and long time span

5. Labor cost is reduced

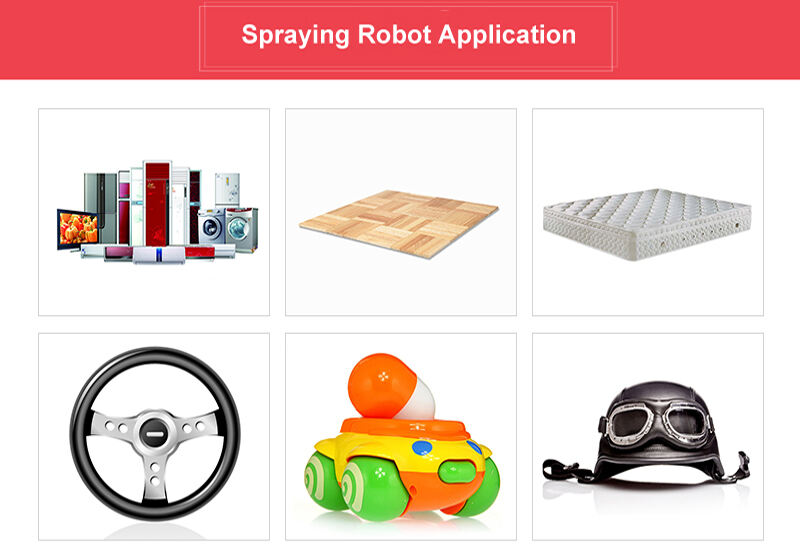

Application:

The five axis automatic spraying reciprocating machine is wildly used in the field of plastic, electronics, hardware handicraft, TV shell, computer panels, kitchen ware, Car and Car parts, bathroom ware, Power industry etc. many fields

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries.From a development department,Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment.After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

Our Service

Pre-sales:

1. Offer professional advice and provide the best solution for the customer

2. According to customer's needs or requirements, Our engineer will offer the drawing and solution for you.

3. We will offer the competitive price according to the customer's solution

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

If you can send us some pics about your product with capacity per day and product size for first reference. Once get your infos, We will send you our solution with price ASAP,Appreciating for your support!!!

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ