Overview

Inquiry

Related Products

Xinqinfeng

PVD coating machine metal will be the ideal solution boosting the look and durability of one's metal products. An even more appearance that is sophisticated, this machine guarantees to provide top-quality outcomes whether you're looking to increase the corrosion resistance, wear resistance or simply just provide your steel.

The gear is suitable for various applications and industries with a robust design and advanced technology. It is perfect for coating metals such as for example titanium, gold, silver, chrome, metal, brass, copper, and aluminum. Additionally, it offers control the exact layer procedure, helping you to attain a uniform coating thickness and an even more constant finish.

The Xinqinfeng PVD coating machine metal is straightforward to utilize, because of its interface is user-friendly and automation features. It features a touch-screen control that presents the real-time parameters method, including the current, voltage, and deposition price. Also, it provides a loading automatic system that means it is an easy task to manage big volumes of products.

Very notable top popular features of this product is it’s environmentally nature is friendly. The PVD coating machine metal process is really a low-temperature procedure that doesn't need any harmful chemical compounds or gases, rendering it a coating solution is eco-friendly. Which means you're able to produce top-quality coatings without fretting about any effect is certainly negative the environmental surroundings.

What's more, the Xinqinfeng PVD coating machine metal is highly dependable, as well as the result is total excellent. It comes having a warranty is one-year together with manufacturer provides installation on-site training, and upkeep solutions to ensure your machine works optimally throughout its lifespan.

| Spray the base UV paint---UV Curing----PVD Vacuum coating machine----Spray the top UV paint---UV curing. |

Overview: Evaporative coating device uses resistance heating method in a vacuum chamber to melt and vaporize the metal wire (aluminum wire) that is close to the resistance wire, and the vaporized metal molecules are deposited on the substrate to obtain smooth and high reflection. The high-efficiency film layer achieves the purpose of decorating and beautifying the surface of the item.

Features: Reasonable structure, uniform film layer, good film quality, high pumping speed, short working cycle, high production efficiency, convenient operation, low energy consumption and stable performance.

Uses: automobiles, audio, various small appliances, computers, watches, toys, mobile phones, reflectors, cosmetics, toys and other industries.

Machinable materials: ABS, PS, PP, PC, PVC, Nylon, Metal, Poly, Glass, Ceramic, TPU, etc.

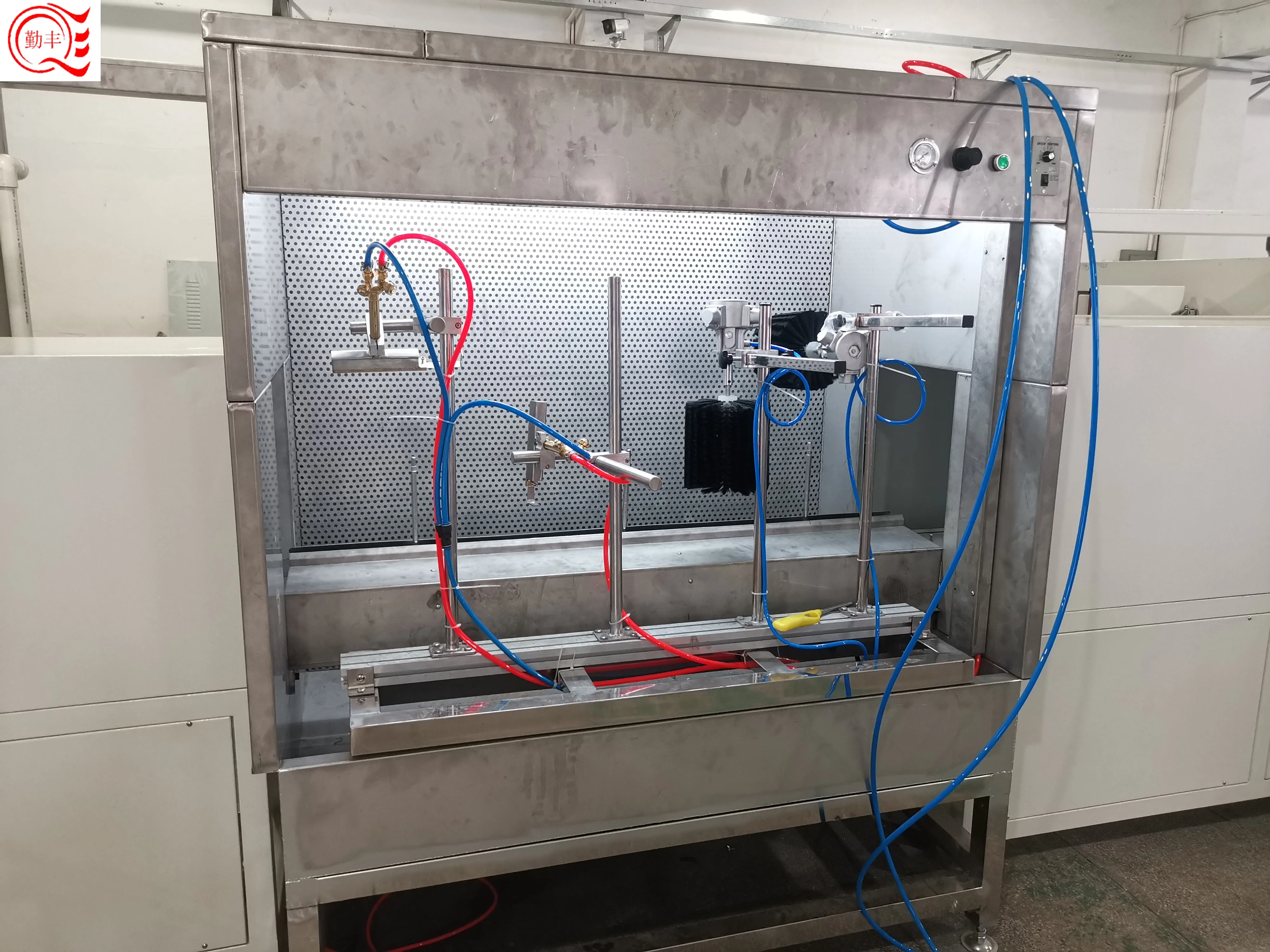

| Product Pictures: |

| Application: |

Automatic spray paint line are widely used to the workpiece which will be achieve high efficiency, high output.

Such as all kinds of bottle, wine bottle, Cosmetics bottles, cosmetic lid, glass cup, glass ball, hardware, plastic round disk, kitchen ware, helmet, rearview mirror etc. irregular shapes

Our Service:

Pre-sales:

1. Offer professional advice and provide the best solution for the customer

2. According to customer's needs or requirements, Our engineer will offer the drawing and solution for you.

3. We will offer the competitive price according to the customer's solution

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

If you can send us some pics about your product with capacity per day and product size for first reference. Once get your infos, We will send you our solution with price ASAP,Appreciating for your support!!!

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ