Overview

Inquiry

Related Products

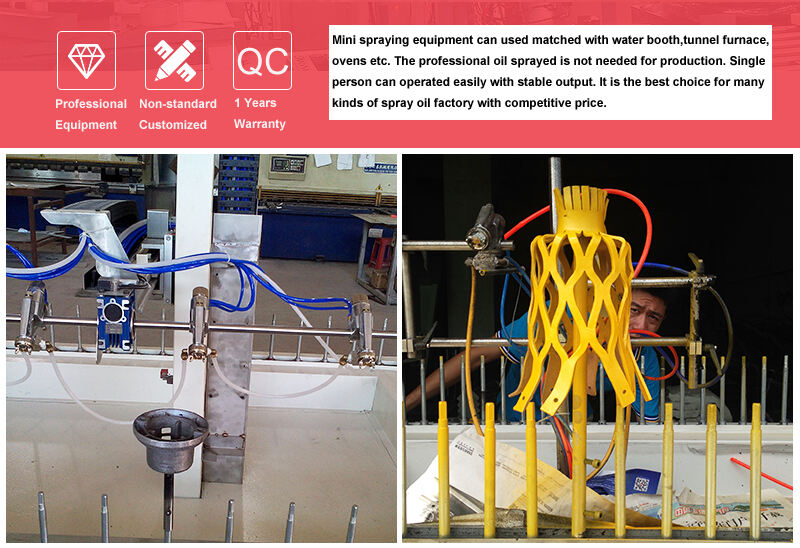

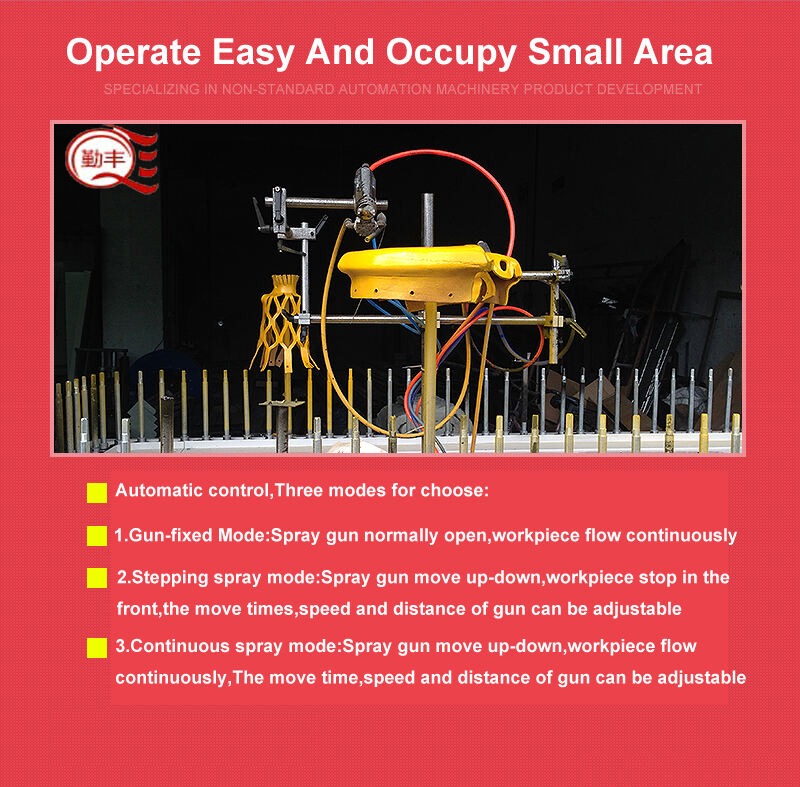

- Operate easy and simple,single person can operate it

- Mini type,Occupy small area

- Automatic spraying,high efficiency, Save labor cost

- Factory Price,Competitive price

- High quality,One year Warranty

- Whole factory plastic parts automatic dust coating equipment

- Whole plant metal products electrostatic coating equipment

- Whole factory furniture electrostatic coating equipment

- Whole plant locomotive, motorcycle coating equipment

- Manipulator, Spraying robot etc Industrial Robot equipment

- Automatic UV curing furnace line

- Fully automatic electrostatic dust removal equipment

- DISK automatic electrostatic coating equipment

- All kinds of Drying,silk-screen equipment

- All kinds of PVC/SUS belt,Nylon conveyor equipment

- Teflon/Ceramic powder /PE immersion high temperature equipment

- All kinds of Water Curtain Booth etc equipment

- High level Air Supply System

- Waste water/waste gas recycling system

- Whole plant electroplating coating equipment

- Whole factory electrophoresis coating equipment

Automatic painting equipment UV Coating machine

Production Features:

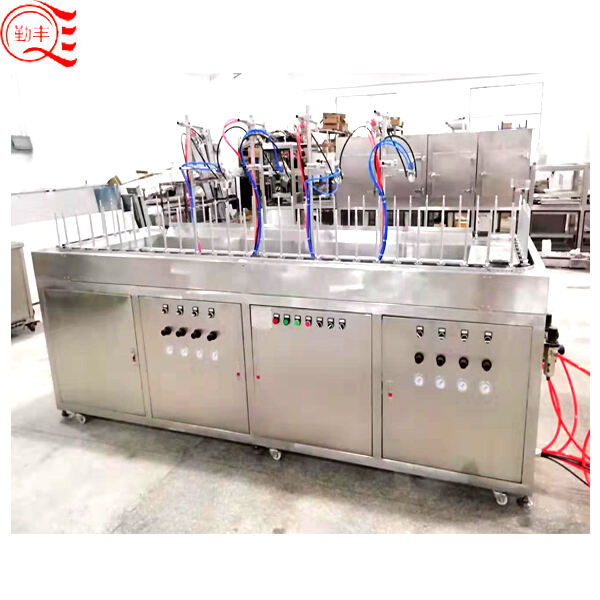

Product Specification:

|

No. |

Item |

Specification |

|

1 |

The external dimension of the Rack |

The dimension: L2700mm x D1000mm x H850mm (1 set) |

|

2 |

The rack |

The rack is made of welding 50# square box section. The bottom of rack has the truckle and foot cup. The height is adjustable. The rack is sealed by the plate,The structure is compact and generous. |

|

3 |

The Conveyor Chain |

The conveyor chain use special chain of automatic line. the pitch is 50.8mm,the total length is 6.4m. Each two pitch distance use one special fixture for the product. |

|

4 |

The Motor |

The motor use Taiwan imported 0.5HP gear reducer motor to transmission. The speed of chain is adjusted by adopting 1HP ZONCN frequency transformer. The chain speed is adjustable within 0.1m/min- 5m/min. The frequency control of the motor speed is energy saving. |

|

5 |

The Friction Rotation Devise |

It has two sets of special friction system, The motor adopts 200W electronic speed regulating motor. It can positive and negative rotation. |

|

6 |

The Electronic Control |

The electronic control is mainly use China famous brand CHINT brand.The indicator light, the switch,relay and contacts are equipped with the overload protection.The parts of Electronic Control is placed in the below of racks. |

|

7 |

The surface treatment |

Computer white electrostatic powder coating |

|

8 |

Paint and Oil Feeding System |

1. The automatic spray-gun use Japan ANEST IWATA WA-101 automatic spray gun. The caliber is 1.0mm. The qty of the guns is six. A set of adjustable support brackets is equipped. 2. Two sets of trisection diaphragm pumps are equipped. 3. It is equipped with relative oil pipe, Air pipe, pressure regulating valve,oil-water separator and a set of electric magnetic Valve. |

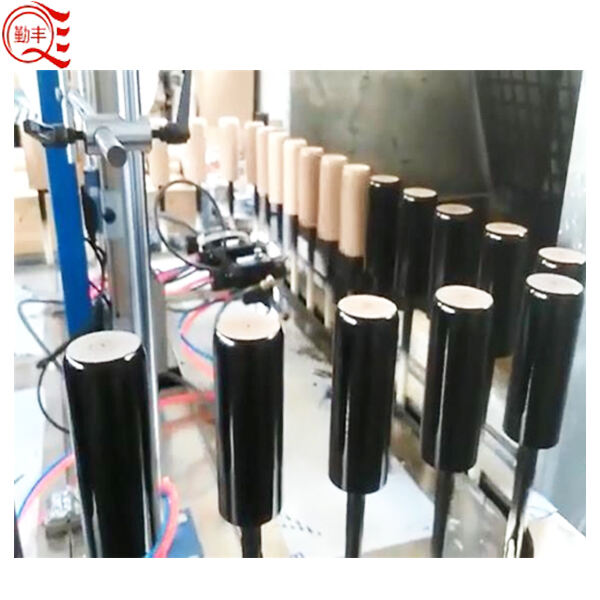

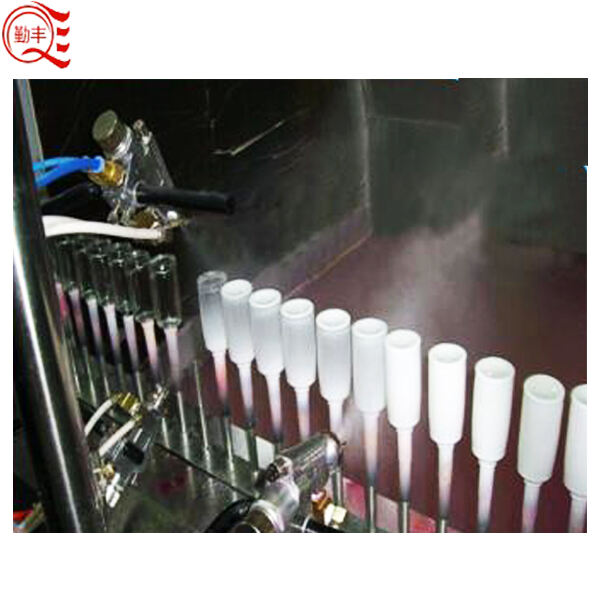

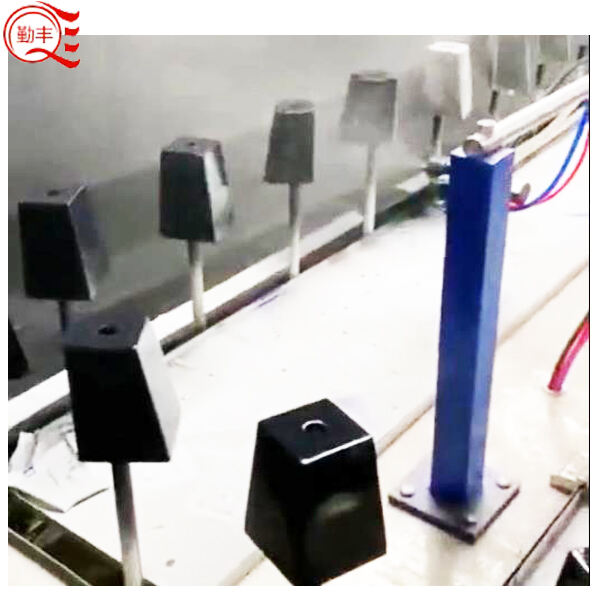

Product Pictures:

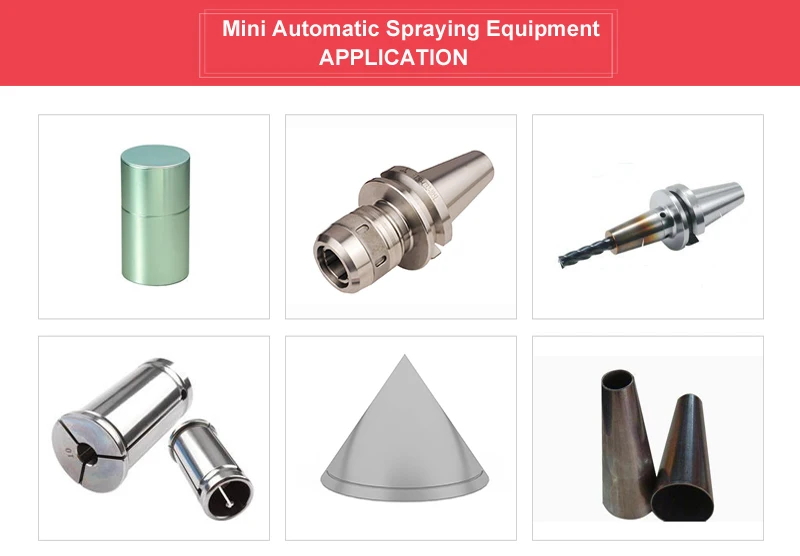

Application:

The Mini automatic spraying machine or Mini automatic spraying painting Line is wildly used in the field of plastic,Metal,stainless,glass,wood etc round,cylindrical,conical shapes or other irregular ,small type shapes' furface spraying,such as cellphone shell,glass cup, lamp shell,helmet,bottles,holder,cosmetics lid etc project.

Shenzhen Xinqinfeng industrial equipment co., LTD. was established in 2004.The products are sold to various regions of mainland China and foreign countries.From a development department,Xinqinfeng has become a professional manufacturers which currently specializing in non-standard automatic mechanical Equipment’s development, design and production, with standard large plant and advanced production equipment.After years of unremitting efforts and accumulation, Now Xinqinfeng specializes in industrial automation equipment with considerable scale and strength.

Main products include industry surface automatic painting, automatic drying, as well as automatic spraying the entire plant planning, designing and manufacturing, as well as industrial robots, robots, automation equipment and other non-standard test equipment.

Main Products:

Company Pictures

Other Hot Selling Equipment :

Packageing & Shipping:

it will packed by the vacuum membrace firstly, Then use the square box section to fixed,finnaly the equipment will be sealed with the wooden frame.

Our Service

Pre-sales:

1. Offer professional advice and provide the best solution for the customer

2. According to customer's needs or requirements, Our engineer will offer the drawing and solution for you.

3. We will offer the competitive price according to the customer's solution

After-sales:

1. We will send the engineers for onsite installation, commissioning and operation training.

2. We will provide fault handing service and lifetime warranty.

3. We provide 1 year warranty for each machine.

4. We will contact you back periodically to learn machine conditions.

5. We also provide the service for further extension on your existing machine.

FAQ

Question 1: I don't know anything about the machine. Will you provide the technical support?

Answer: Sure. Every machine will be test before delivery. We will make sure there is no problem for the machine while it leave our factory.

When the equipment is small and standard ,such as five axis spraying equipment,mini spraying line, small tunnel furnance or ovens,spraying power booth,curing furnace etc, We can send the detailed user manual and video to

help you install and operate the equipment. Of course,You can arrange 2-3 smart workers to come to our factory to learn how to operate the machine.

If the machine is spraying line and big,When the machine arrives your factory, we will send the experts to your factory to help for installation and commissioning. Operation training will be provide. Maintenance tips will be given and enough spare parts be provided.

Also, we provide consulting service for creating the proper facilities for running the machine.

Question 2: What is price of the machine?

Answer: Normally, Most of the machine is customized for our customer. If you have any drawing or any information on specification of the machine, please send to us for quote.

If you are totally new in this area, please send us the detail infos about your workpiece as blow:

1. The maximum size of workpiece:

2. The max weight of workpiece:

3. The output per month/per day:

4. Heating Temperature and Time(If you need the drying equipment):

5. Color changing(How many colors? How long will it take to change other colors ?)

6. Spraying process(What paint will you use? Spraying times? )

7. The workshop size for the equipment:

8. Some work-piece pics are needed:

9. The power: industrial three phase voltage

10. Other requirements from customer:

We will provide our professional suggestions and work out an appropriate design for your project.

Then the quotation with detail specification will be offered to you ASAP.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

HY

HY

BN

BN

LA

LA

MY

MY

UZ

UZ