Introduction to Curing Oven

Curing Ovens are crucial in the manufacturing industry for curing and drying materials. They are used to apply heat to substances that need to be solidified or hardened, which includes coatings, adhesives, and composite materials. Curing ovens and also Xinqinfeng uv painting have become increasingly popular in recent times due to their efficiency and affordability, essential for many businesses.

In elementary terms, curing ovens are like big ovens that use heat to cook things that need to become hard. These ovens are essential in industries where they have to make things like furniture or other goods.

One of the most significant advantages of using a curing oven in the manufacturing process is that it ensures the material being processed is cured more uniformly. This way, it is possible to achieve better-looking and higher quality end-products. The heat settings of a curing oven can be easily controlled, allowing the user to adjust the temperature, time, and even heat distribution.

Another benefit of using a curing oven is that it can reduce lead times and save money spent on material handling and transportation. This is because the entire curing process can be done in-house, thereby eliminating the need for shipping materials between different sites.

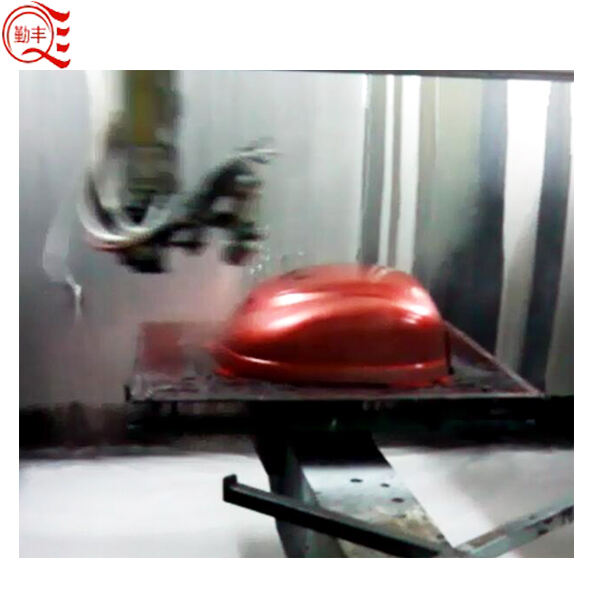

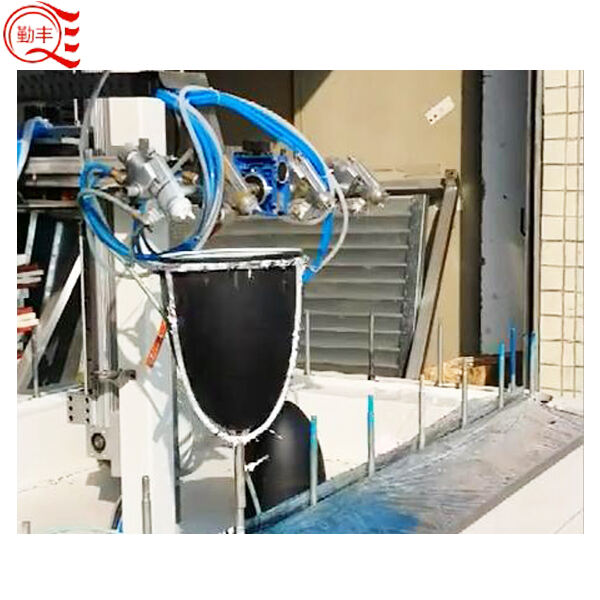

The use of curing ovens and even Xinqinfeng UV Spray paint line has also increased efficiency in many industries, reducing the work time needed to process these materials while also providing better quality and consistency.

In, using a curing oven has many benefits. These ovens produce higher quality end-products because the heat is evenly distributed throughout the material. Also, using a curing oven saves time and money, as everything happens in-house, and the process is more efficient.

There have been several innovative features added to curing ovens in recent times, including safety sensors and advanced software. These features work together to prevent any potential accidents or incidents that could harm workers or damage the product being cured.

Curing ovens of Xinqinfeng are also designed with safety in mind, and they come with several safety features such as over-temperature protection, flame supervision, and explosion-proof design. This reduces the risk of fire and other hazards, making the oven safe to use.

In elementary terms, curing ovens have many safety features built into them that help prevent accidents or injuries. These features include things like temperature control and flame supervision, which keep everything safe.

To use a curing oven or the Xinqinfeng paint spray machine, there are a few steps that need to be followed. First, ensure that the oven is clean with no obstructions and is free from contaminants that could damage the product. Then, check the temperature and time settings and adjust them to the required levels.

The next step is to load the product into the oven using appropriate equipment to avoid contamination and damage. Finally, start the curing process, ensuring the temperature, humidity, and other factors are continuously monitored to ensure a successful cure.

In, to use a curing oven, the oven must first be cleaned and make sure nothing may damage the product. Then, set the temperature and time, load the product, and start the process, making sure to keep everything monitored.

When investing in a curing oven or even to Xinqinfeng painting robot price, it is essential to ensure that it is of high quality and that the manufacturer provides good after-sales service. This is important because it ensures that all issues and concerns are addressed and resolved promptly.

Curing ovens have various applications in various industries, including chemical, automotive, aerospace, and medical, among others. The curing process is critical in these industries since it ensures that high-quality end-products are produced, which meet the desired industry standards. It is important to buy a high-quality curing oven and make sure the manufacturer provides good after-sales service. Curing ovens have many applications across different industries, making them important for ensuring high-quality end-products.

Xinqinfeng factory has rich experienced engineers workers as we have more than 20 years Curing Ovenin liquid spraying coatings powder coating. offer a wide range of the machines for almost all kinds products, from cosmetic bottles to car,from wooden glass etc,for paint such as water based paint, varnish, UV paint etc.The years of experience allow us to the design speedy and rapid production.

Xinqinfeng been specializing in AUTO Coating equipment more than 20 years. can offered Non-customized service,one stop coating service from cleaning,spraying,Curing Oven,metallic coating,powder coating etc.From production installation,paint,paint teacher,air compressor ,can Provide key services to make customers more worry free achieve rapid mass production.

Xinqinfeng specialized in Auto Spray Paint Machine, full-auto Curing Oven drying line,Industrial oven,UV Curing furnace,PVD Coating machine,Robot spraying paint line 20 years.Our machine has been exported various countries, like North America, Europe Middle East, South America, Middle East, West African other countries,Many machines has CE Certification.

Xinqinfeng uses high-quality materials parts to make machine. These include top of line metal components, imported spraying Curing Ovenguns made from Taiwan, best electronic brands as well as Taiwan company PLC.Our engineers and workers have experience to ensure that each step is ideal solution.Xinqinfeng has a good reputation in customers,nowadays,90% of our customers are from overseas.