Introduction:

In today's modern world, different companies are in search of better methods to increase their production capacity with better security and quality control, as well as the Xinqinfeng's automatic paint line. Among the innovations inside the industry is the coating production line, created to enhance the production process. The coating production line is a machine that applies coatings to various materials enhance their look, durability, and other properties.

The coating production line has several advantages traditional coating methods, just like the domestic paint sprayer by Xinqinfeng. Firstly, it offers increased production output and reduced labor because it eliminates the requirement for manual intervention. The coating production line also ensures consistency in the coating finish, challenging to achieve making use of traditional methods. Additionally, it could apply coatings to a wide variety of, including metals, plastics, and ceramics.

The coating production line is a development in the industry, which uses cutting-edge technology to improve the production process, as well as the Xinqinfeng's paint sprayer for exterior paint. It permits manufacturers to produce high precision the coating application process, ensuring high-quality finished products. Moreover, it integrates advanced quality control systems, which makes it easy to identify defects and flaws in the coating process.

The coating production line happens to be made out of security as a top priority, similar to the spray painting line innovated by Xinqinfeng. It has a minimal risk workers it eliminates the necessity for handbook intervention in the coating process, decreasing the likelihood of injuries. In addition, it incorporates safety features such as alarms and emergency end buttons to minimize accidents.

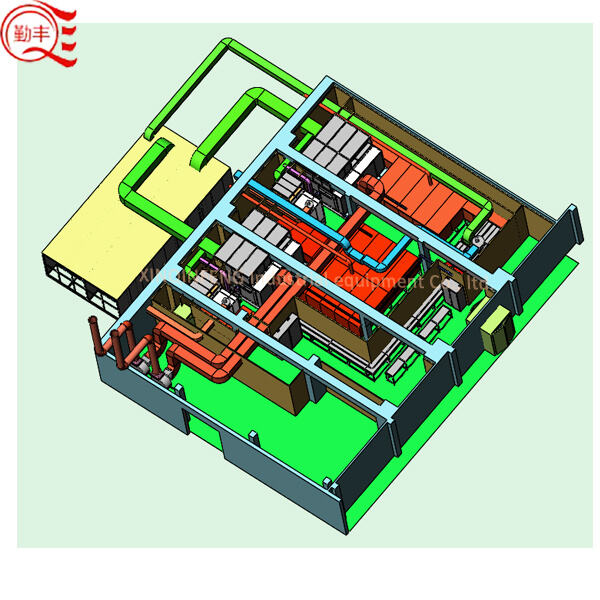

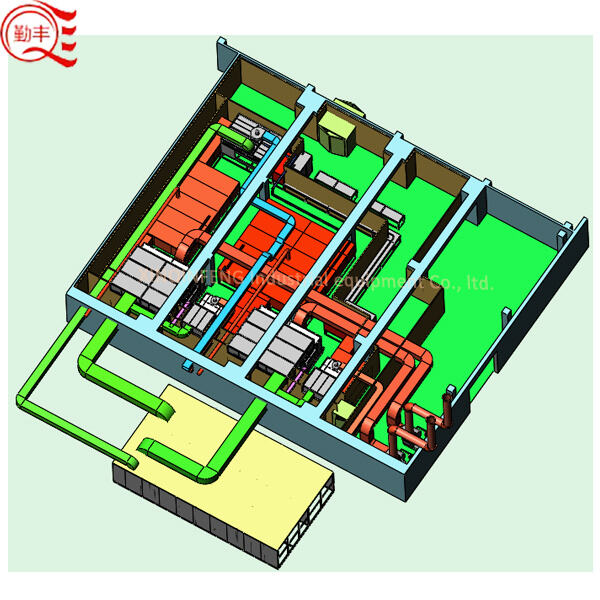

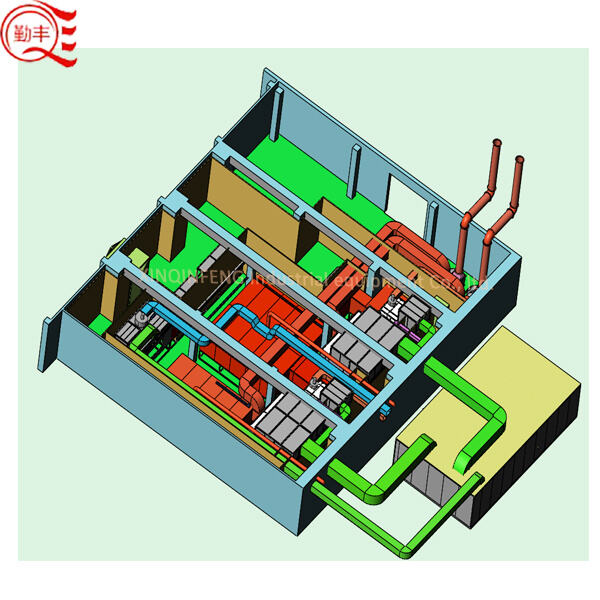

The coating production line is easy to use, plus the process is simple and uncomplicated, the same as Xinqinfeng's automatic paint machine. Firstly, the materials to be coated is positioned on the conveyor belt, which moves it through the coating chamber. The coating material will be sprayed on top to be coated using automated systems. The materials will be dried, and also the procedure completes within a short interval.

Xinqinfeng uses high-quality materials parts to make the machine. These include top of line metal Coating production lineincluding imported spraying paint guns from Taiwan, best electronic brands Taiwan brand PLC.have skilled engineers and worker,to ensure every process is optimal, from design production.Xinqinfeng has good reputation in customers,nowadays,90% of our customers from overseas.

Xinqinfeng specialized in AUTO Coating machine for more than 20 years. can offered the Non-customized service,one stop coating service from cleaning,spraying,drying,metallic coating,Coating production linecoating etc.From production installation,paint,paint teacher,air compressor ,can Provide key services make customers more worry free and achieve rapid mass production.

Xinqinfeng specialized in the auto spray paint machine, full-auto spraying drying line,Industrial oven, UV Curing furnace PVD coating machine, Robot spraying paint line for 20 Coating production line.Our machine exported for several countries, such as North America, European South America, Middle Eastern, West African and other countries. Many machines CE Certification.

Xinqinfeng Factory has highly skilled engineers technicians with 20 years knowledge in powder coating liquid coating. have full ranges of Coating production lineall types of items, from wooden to glass, cosmetic bottles more. For water-based paints like paints, vanish, UV paints, etc.

To use the coating production line, you will want to follow along side these simple steps

Step 1: Prepare the material to be coated and place it from the conveyor belt.

Step 2: Set the heat and humidity amounts to your recommended values, as well as the painting robot supplied by Xinqinfeng.

Step 3: Select the kind and thickness of the coating you intend to apply.

Step 4: Start the coating process through the control board.

Step 5: Monitor the process and then make any necessary adjustments.

The coating production line service is key to ensure maximum performance efficiency, same with Xinqinfeng's glass bottle spray painting machine. Regular maintenance is necessary to help keep the equipment in good working condition, preventing breakdowns and improving longevity. In addition, manufacturers should make sure that the production line is calibrated frequently to keep high-quality performance.

The coating production line guarantees high-quality coating finishes constant due to the desired standards, as well as the electrostatic painting machine from Xinqinfeng. It ensures that coatings adhere precisely to your material, essential in enhancing the material's durability, aesthetics, and functionality. The fine and precise spray of the coating end up in a straight appearance no defects.