The process is called vacuum coating unit technology and it's a neat way to make things shiny and protect them from scratches. Xinqinfeng builds special machines that use this technology to help factories produce better products. What is happening when these machines are working and what can they do?

Now, thanks to Xinqinfeng’s vacuum coating technology, these factories can ensure from now on that their products are stronger and look, you know, fancy as hell. Here’s how it happens: First, the product goes into the machine, which looks like a large metal box. It will then suck all of the air out from inside, forming a vacuum. Then, specific materials are heated until they become gas. That gas clings to the product, forming a thin film that, when dense enough, makes it shiny and tough.

Just try to visualize a phone that does not get scratched and looks really cool! Frequently, factories need a vacuum coating unit from Xinqinfeng to make their products look good. Whether it’s a phone, a car part, or even a piece of jewelry, our machines leave them looking sleek and professional. No dull items anymore – just shiny and eye-catching.

Old methods of product production can also be slow and not so good for the environment. But by having the vacuum coating unit of Xinqinfeng, factories can make their production more faster and better! You see, our machines are fast and efficient, which means that they help factories churn out a greater amount of products in less time. Plus, since they are built with safe materials, there is less waste and pollution. It's a win-win for everyone!

Work Smarter with Vacuum Coating Trend 3: TruSoy Wax Jump Freund-Vector's 25 kW induction vacuum system, equipped with a compact wax tank, is the perfect choice for applications involving continuous flows of wax.

The vacuum coating technology from Xinqinfeng not only makes products more visually attractive but it also allows factories to operate in a smarter way. Factories can get better at working by using our machines.’ That means less error and more joyous customers. What’s more, products that look cool and last longer can command more money in the factory, resulting in more profits!

Now that’s something that Xinqinfeng’s vacuum coating machine can do, and it’s a special one, one that might alter the way factories produce. Our machines show factories how coating technology can look in the future. Our machines are intelligent, combustion machines that help factories outpace the competition. With vacuum coating unit of Xinqinfeng, everything is possible!

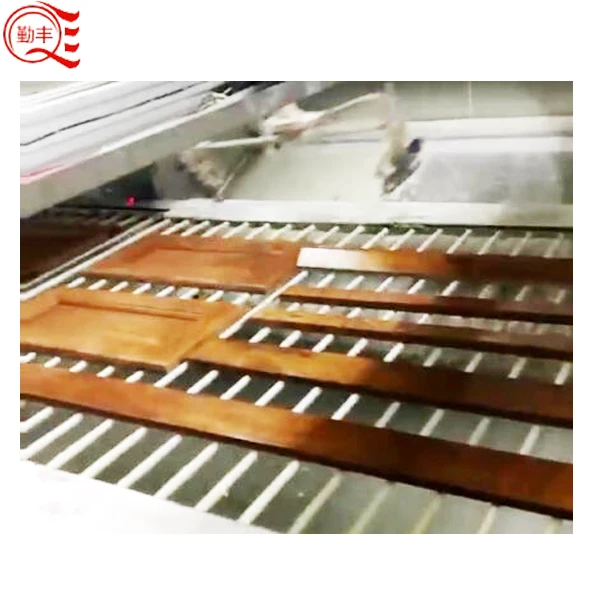

Xinqinfeng specialized in AUTO Coating machine for past 20 years. We can offered Non-customized service,one stop coating service from vacuum coating unit,spraying,drying,metallic coating,powder coating etc.From production installation,paint,paint teacher,air compressor ,We can Provide key services make customers more worry free and achieve rapid mass production.

Xinqinfeng Factory home to skilled engineers and employees with 20 years knowledge in liquid coating powder coating. have full ranges of machines suit all products, from wood to glass, vacuum coating unitbottles, more. For paint water based paint, vanish,UV paint, etc.

Xinqinfeng been specialized auto-spray paint machines and complete automatic spraying drying lines for more than 20 years.equipment been exported to a variety countries, including Europe, North America, South America vacuum coating unitEast, West Africa others.

Xinqinfeng employs top-quality materials components for machine. These include first class metal parts, imported spraying paint guns from Taiwan, best electronic brands and Taiwan company PLC.We have seasoned workers engineers to ensure that each process designed to be the most efficient, right from conception manufacturing.Xinqinfeng has good vacuum coating unitcustomers,nowadays,90% of our customers are from overseas.