Introduction

Looking for an efficient way to apply a protective layer your products or services? Companies can find the traditional coating method, but it could be time-consuming and leave unwanted streaks areas that were missed, as well as the Xinqinfeng's electric paint sprayer for cars. Introducing the spray coating line, a newer and innovative way complete the job with ease. Below are a few explanations companies should consider integrating a spray coating line their manufacturing process.

One of the main great things about a spray coating line is decreased production time, the same as paint line spray made by Xinqinfeng. The process is quicker than manual application, improving production speed and reducing potential errors. The automated process also makes it easier to attain an even coating, ultimately causing consistent quality this final product. Additionally, the spray coating line is much more versatile than old-fashioned methods, allowing companies to apply coatings to different surfaces, sizes, and shapes by just adjusting the spray settings.

As technology improvements, innovation is vital in creating new items is efficient and practical, identical to Xinqinfeng's product interior paint sprayer. The introduction of the spray coating line has revolutionized the coating industry, rendering it faster, safer, and much more accurate. The technique also reduces waste, thanks to the precise application of, which minimizes over-spraying or run-off.

Safety is always a priority, particularly in high-risk industries such as manufacturing, also the coating spray machine created by Xinqinfeng. Using a spray coating line reduces the possibility of injury for employees, because it is a more automated process eliminates the necessity for manual labor. Additionally, the use of protective gear is simpler and more comfortable for workers because they do not need to worry about coating their clothing or skin. Companies can also reduce their carbon footprint by utilizing eco-friendly coatings in their spray coating lines, improving worker and customer safety and reducing problems for the surroundings.

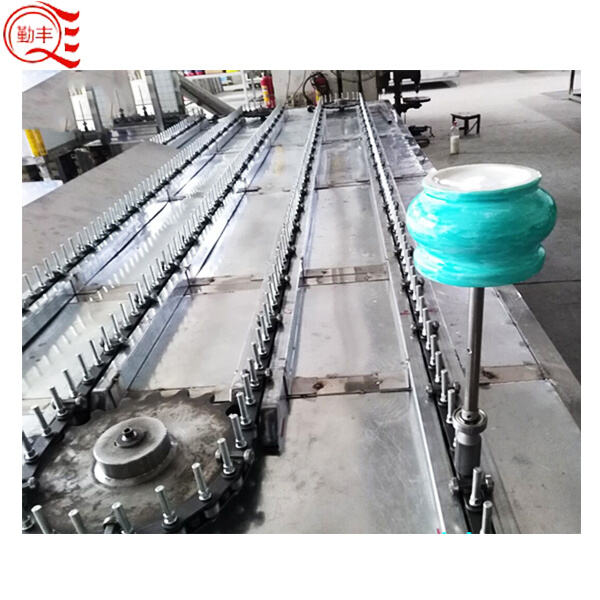

Using a spray coating line is relatively effortless, similar to the Xinqinfeng's product like electric paint sprayer for cars. First, the product to be coated must be prepared, with surfaces being cleaned and primed for better adhesion. This product will be placed on the moving conveyor, which carries it through the coating enclosure. The spray coating is applied evenly, and excess particles removed through the automated filtration system in this time around. Finally, the merchandise is cured, typically through a baking process, before moving towards the next phase production.

Xinqinfeng utilizes high-quality components as well as parts the machine. These include first class metal components, imported spraying paint guns made from Taiwan top electronic brands as well as Taiwan company PLC.Our engineers and workers have experience to ensure that each step is ideal Spray coating line.Xinqinfeng has good reputation customers,nowadays,90% of our customers from overseas.

Xinqinfeng Specialized in the auto spray paint machine, full-auto spraying drying line, Spray coating lineoven, UV Curing furnace and PVD coating machine,Robot spraying line twenty years.Our machine has been exported to various countries, like North America, Europe South America, Middle Eastern, West African other countries. A lot of our machines CE Certification.

Xinqinfeng Factory staffed by experts in field of engineering and has twenty years expertise in liquid coating as well as powder Spray coating line. offer a wide range of machines to suit all products, ranging from wooden glass, to cosmetic bottles and more. Water-based paints, such as paints, vanish, UV paints, and more.

Xinqinfeng specialized in AUTO Coating machine for past 20 years. We can offered Non-customized service,one stop coating service from Spray coating line,spraying,drying,metallic coating,powder coating etc.From production installation,paint,paint teacher,air compressor ,We can Provide key services make customers more worry free and achieve rapid mass production.

Service is crucial in ensuring the smooth running of any machinery, and the spray coating line is not any exception, as well as the UV coating line manufactured by Xinqinfeng. Companies that spend money on a spray coating line should try to find support also services which will help maintain and repair the apparatus properly. Many providers provide preventative maintenance programs that include regular inspections, testing, repairs, and replacements, making sure the operational system runs efficiently for many years in the future.

Quality is a top priority any company, and the spray coating line often helps reach that goal, along with Xinqinfeng's product mini spray paint machine. The automated process ensures consistent coverage decreasing the likelihood of defects or missed spots. Any problems or errors can be easily identified, and so the operational system can be calibrated to correct the problem. Furthermore, the spray coating line may be customized for particular products, ensuring the coating is applied just as required by the manufacturers.

The spray coating line can be used in numerous industries, ranging from automotive to packaging to appliance manufacturing, similar to the automatic paint spray line by Xinqinfeng. The versatility for the system causes it to be a valuable addition to any production line, providing an easy, accurate, and consistent application. Companies may also use the equipment to use specialized coatings, such as anti-corrosive or UV-resistant coatings, enhancing the final product quality and durability.