Did you ever think about how cars, toys or even our Xinqinfeng products are being produced? A curing oven is an important tool in the making of many of the objects we use every day. In this article, we will look at what curing ovens are, how they work, and their significance.

Curing ovens, or heating systems, are specialized machinery that initiate drying of materials (paints, coatings, adhesives) through heat. The heat causes these materials to harden and set, allowing for its use in various products such as cars, furniture and electronic devices.

Curing ovens speed up the manufacturing process. Before the invention of curing ovens, workers were forced to wait long hours for the materials to dry naturally. With curing ovens, materials can dry much faster and workers can produce more products in less time.

Some of these justifications will be discussed below, as there are many reasons as to why these ovens are used in the factory environment. One large factor is the uniform and thorough drying ensured by curing ovens. This can lead to better quality and stronger products. Curing ovens also allow for a more efficient process, reducing waste and the time and costs associated with fixing errors in manufacturing.

Let us now examine the types of curing ovens. There are batch ovens, conveyor ovens, and infrared ovens. Batch ovens cure small quantities of materials, conveyor ovens cure materials on a production line. Infrared ovens cure materials quickly and evenly using special light.

And some tips to improve the performance of curing ovens. A major tip is to prepare everything well in advance of when it goes in the curing oven. Could help make sure materials cure evenly. You should also follow the curing oven's operating instructions, as various ovens have different requirements for determining curing materials.

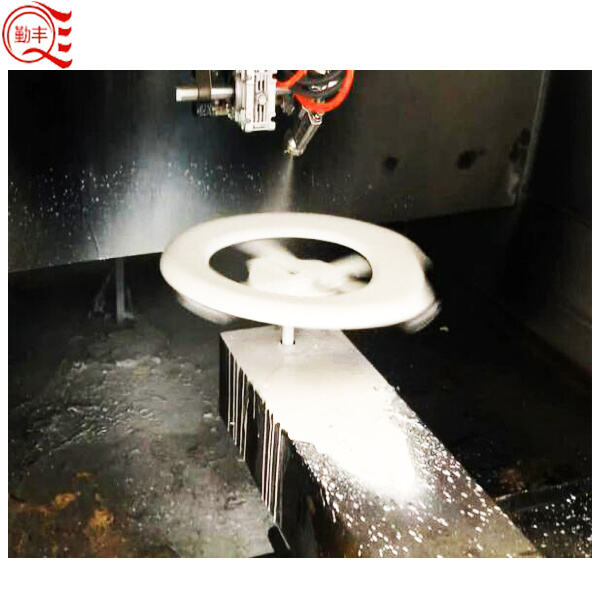

Xinqinfeng specialized in AUTO Coating machine for more than 20 years. can offered the Non-customized service,one stop coating service from cleaning,spraying,drying,metallic coating,curing ovencoating etc.From production installation,paint,paint teacher,air compressor ,can Provide key services make customers more worry free and achieve rapid mass production.

Xinqinfeng utilizes high-quality components components for machine. This includes top-quality metal components as well as imported spraying paint guns made from Taiwan the best electronic brands as well as Taiwan brand PLC.team of engineers technicians have years of experience and know-how ensure each curing ovenis the most effective solution.Xinqinfeng has a good reputation in customers,nowadays,90% of our customers are from overseas.

Xinqinfeng specialized in the auto spray paint machine, full-auto spraying drying line,Industrial oven, UV Curing furnace PVD coating machine, Robot spraying paint line for 20 curing oven.Our machine exported for several countries, such as North America, European South America, Middle Eastern, West African and other countries. Many machines CE Certification.

Xinqinfeng Factory has highly skilled engineers technicians with 20 years knowledge in powder coating liquid coating. have full ranges of curing ovenall types of items, from wooden to glass, cosmetic bottles more. For water-based paints like paints, vanish, UV paints, etc.